This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

PRESSES AND ROLLERS

ISOSTATIC POWDER PRESSES

Isostatic powder presses enable fully automated forming of components close to their final shape, thus making it possible to produce design geometries in large quantities without compromising quality.

For round, square, rectangular and oval ceramic parts up to 480 mm, 1 to 3 cavities with a closing force of 2000 to 7000 kN and isostatic pressure of 300 bar.

For thin-walled technical ceramic pipes with a thickness of 1.2 to 2 mm and a maximum length of 350 mm with a closing force of 400 to 600 kN and an isostatic pressure of 2000 to 2300 bar.

For thick pipes and thin and heavy technical ceramic rods up to 450 mm in length with a closing force of 600 kN and isostatic pressure: 2000 bar.

For shafts, axles, tubes, bushings, nozzles, spheres up to 8 cavities with a closing force of 600 kN and an isostatic pressure of 2000 bar.

APPLICATIONS

Household tableware and ceramics, solid-state ceramic electrolyte substrates for sodium-sulphur or sodium-nickel-chloride batteries (ZEBRA batteries). Line automation options are available including granulate supply, the press and the tool system.

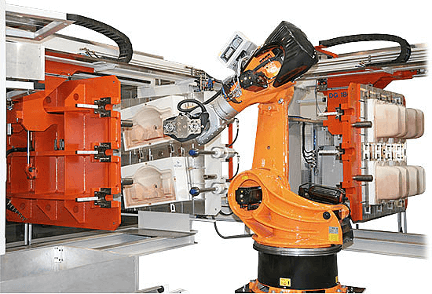

PRESSURE CASTING SYSTEMS

They enable the forming of articles close to their final shape, making it possible to produce uniform geometries with considerable demands on casting and design in medium or large quantities in a cost-efficient way without compromising quality.

For sanitary ware with pressing force from 600 to 3000 kN, 2- to 7-piece moulds, 2 to 6 cycles/h.

For tableware with pressing force from 1200 kN, 2-piece mould, 10 to 40 cycles/h.

APPLICATIONS

Crockery, vases, bottles, hollow or solid casting, lavatories, washbasins, kitchen sinks, shower trays and ceramic slip basins. Robotised line.

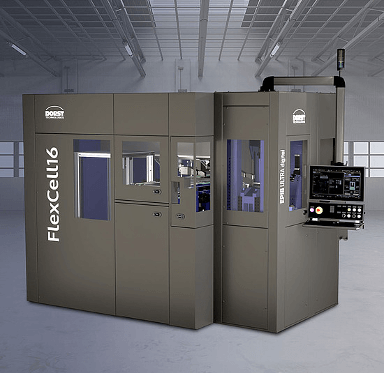

VACUUM EXTRUSION PRESSES

Particular robustness, durability and wear resistance are the prominent features of the DORST vacuum extrusion presses we offer which have been specially developed in terms of both machine design and technical engineering for the extrusion of heavy or very abrasive materials. The presses can be used almost universally and operated anywhere, whether horizontally or vertically, depending on the application.

Key features include a central vacuum chamber for high-density materials and modern frequency-controlled electric drives and the possibility of very precise sectional temperature control of the material on both the feed and press side to achieve high-quality production results with high repeatability. A modern, network-capable process control system is used for visualisation, operation and evaluation of all process data.

ROLLERS

Lippert has developed NC-roller technology for the ceramics industry with maintenance-free three-phase servomotors which perform all vertical and horizontal axis movements by means of high-precision screw ball rollers. The stability of the guide ensures highest product quality. This technology is implemented in a wide range of rollers for every task in these series:

- Single roller

- Single and double roller with turntable

- Carousel production line

- Bowl, cup and plate production line

ADVANTAGES

The Lippert NC-rollers technical concept allows very variable and fine settings options, the highest precision in roller head movements and exactly reproducible production processes. In terms of production, this means:

- Best plastic shaping procedure for each specific article

- Producing extraordinary and complicated articles

- Reduced thickness for very thin and fine porcelain and bone china

- Reliable high product quality over time

- Extremely fast retooling times as the product line changes instantly

- Simultaneous production of different products with double-head rollers